Do You Know The Importance Of Air Loop Gaskets In Noise Reduction?1

Are you tired of dealing with excessive noise in your home or workplace? If so, then you may want to consider the importance of air loop gaskets in noise reduction. These often-overlooked components play a crucial role in soundproofing your space and creating a more peaceful environment. In this article, we will explore the benefits of air loop gaskets and discuss how they can make a significant difference in reducing unwanted noise. Keep reading to learn more about the impact of air loop gaskets and how they can help you achieve a quieter and more comfortable setting.

- Understanding the Function of Air Loop Gaskets in Noise Reduction

Air loop gaskets are an essential component in noise reduction systems, playing a crucial role in controlling the flow of air and minimizing sound transmission. These gaskets are commonly used in various applications such as HVAC systems, air handling units, and industrial machinery to provide a reliable seal and prevent noise leakage.

One of the primary functions of air loop gaskets is to create a tight seal between different components of a system, such as ductwork or equipment enclosures. By sealing gaps and joints, air loop gaskets help to prevent air leaks, which can lead to a loss of energy efficiency and increased noise levels. These gaskets are designed to be flexible and compressible, allowing them to adapt to the irregularities of surfaces and provide a secure barrier against air and sound.

In addition to sealing air leaks, air loop gaskets also serve as a barrier to the transmission of noise. When installed properly, these gaskets can significantly reduce the amount of noise that escapes from a system, improving the overall acoustical performance of the space. This is particularly important in residential and commercial buildings where noise pollution can have a negative impact on the occupants' comfort and well-being.

Furthermore, air loop gaskets play a critical role in maintaining the efficiency and performance of HVAC systems. By preventing air leaks and controlling the flow of air, these gaskets help to optimize the operation of heating, ventilation, and air conditioning equipment. This not only results in energy savings but also contributes to a quieter and more comfortable indoor environment.

When selecting air loop gaskets for a specific application, it is important to consider factors such as material composition, thickness, and compressibility. The choice of material can impact the gasket's durability, resistance to environmental factors, and ability to maintain a tight seal over time. Additionally, the thickness and compressibility of the gasket will determine its effectiveness in sealing gaps and reducing noise transmission.

In conclusion, air loop gaskets play a vital role in noise reduction by sealing air leaks and controlling the flow of air in various systems. By understanding the function and importance of these gaskets, engineers, designers, and building owners can optimize the performance of their HVAC systems and create a more comfortable and quiet environment for occupants. As technology continues to advance, the development of innovative materials and designs for air loop gaskets will further enhance their effectiveness in noise reduction applications.

- The Role of Air Loop Gaskets in Creating an Effective Sound Barrier

In the world of soundproofing, air loop gaskets play a crucial role in creating an effective barrier against noise. These small but powerful components are often overlooked, yet they are essential for achieving optimal sound reduction in various environments. In this article, we will delve into the importance of air loop gaskets and how they contribute to noise reduction.

Air loop gaskets are designed to seal the gaps and spaces in doors, windows, and other openings where sound can easily travel through. By creating a tight seal, these gaskets prevent the transfer of sound waves from one side of the barrier to the other. This is especially important in environments where noise levels need to be controlled, such as in offices, recording studios, or residential buildings.

One of the key benefits of air loop gaskets is their ability to improve the overall acoustics of a room. By sealing off gaps and leaks, these gaskets help to reduce unwanted noise from entering or leaving a space. This is crucial for maintaining a peaceful and quiet environment, especially in places where privacy and concentration are important.

In addition to reducing noise levels, air loop gaskets also play a role in improving energy efficiency. By preventing air leakage, these gaskets help to maintain a consistent temperature inside a room, resulting in lower energy costs for heating and cooling. This is particularly advantageous in commercial buildings where energy consumption is a significant concern.

Another important aspect of air loop gaskets is their versatility and ease of installation. These gaskets come in various sizes and materials to suit different applications, making them suitable for a wide range of projects. Whether you are soundproofing a home office or a recording studio, air loop gaskets can be easily installed to provide effective sound insulation.

Furthermore, air loop gaskets are cost-effective solutions for noise reduction. Compared to other soundproofing methods, such as acoustic panels or soundproofing curtains, air loop gaskets are relatively inexpensive and offer long-lasting results. This makes them an ideal choice for budget-conscious individuals or businesses looking to improve their sound environment without breaking the bank.

Overall, air loop gaskets are an essential component in creating an effective sound barrier. Their ability to seal off gaps and reduce noise levels makes them a valuable tool for achieving optimal acoustics in any environment. Whether you are looking to maintain peace and quiet in your home or improve the acoustics of a recording studio, air loop gaskets are a simple yet effective solution for noise reduction.

- Benefits of Using Air Loop Gaskets for Noise Control in Various Applications

Noise pollution is a pervasive issue in various industries and applications, from manufacturing plants to HVAC systems and beyond. Excessive noise can not only be a nuisance to those in the vicinity, but it can also be a health hazard for workers exposed to high decibel levels on a regular basis. In an effort to combat this issue, the use of air loop gaskets has emerged as a viable solution for noise reduction in a wide range of applications.

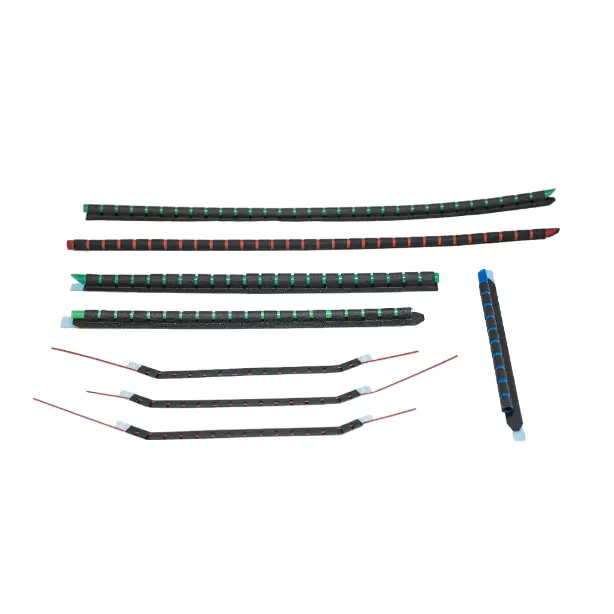

Air loop gaskets are a type of sealing material that is designed to eliminate the passage of air and noise between two adjoining surfaces. This innovative technology consists of a series of interconnected loops that create a barrier against sound transmission, effectively reducing the level of noise that escapes from a given area. By employing air loop gaskets in various applications, businesses and industries can significantly diminish noise pollution and create a safer, more comfortable environment for workers and employees.

One of the key benefits of using air loop gaskets for noise control is their versatility. These gaskets can be customized to fit a wide range of shapes and sizes, making them suitable for use in a diverse array of applications. Whether it's sealing off a noisy HVAC system, containing the sound of a manufacturing process, or reducing noise in a commercial building, air loop gaskets can be tailored to meet the specific needs of any environment.

In addition to their versatility, air loop gaskets are also highly effective at reducing noise levels. The interconnected loops of the gasket create a labyrinthine path for sound waves to travel through, effectively damping and absorbing noise before it can escape into the surrounding area. This not only helps to create a quieter environment for workers, but it also minimizes the risk of hearing damage and other health issues associated with prolonged exposure to high levels of noise.

Furthermore, air loop gaskets are a cost-effective solution for noise control. Compared to other noise reduction methods, such as soundproofing materials or acoustic barriers, air loop gaskets offer a more affordable and efficient way to minimize noise pollution. Their ease of installation and low maintenance requirements make them a practical choice for businesses looking to improve the acoustic quality of their facilities without breaking the bank.

Overall, the importance of air loop gaskets in noise reduction cannot be overstated. From their versatility and effectiveness to their cost-efficiency, these innovative sealing materials offer a comprehensive solution for combating noise pollution in a variety of applications. By incorporating air loop gaskets into their noise control strategies, businesses and industries can create a quieter, safer environment for their employees and customers alike.

- Factors to Consider When Selecting Air Loop Gaskets for Noise Reduction

Noise reduction is a crucial factor to consider in various industries, especially in environments where heavy machinery or equipment is constantly running. One effective way to reduce noise pollution in these settings is by using air loop gaskets. These gaskets play a significant role in minimizing noise levels by creating a tight seal between the surfaces they are placed on. However, selecting the right air loop gaskets for noise reduction requires careful consideration of several factors.

One of the most important factors to consider when choosing air loop gaskets for noise reduction is the material they are made of. The material used in the construction of the gasket can significantly impact its effectiveness in reducing noise levels. Common materials used for air loop gaskets include rubber, foam, and silicone. Each material has its unique properties that affect its ability to dampen sound. For example, rubber gaskets are known for their durability and flexibility, making them ideal for high-pressure applications. On the other hand, foam gaskets offer excellent sound absorption properties, making them suitable for reducing noise levels in sensitive environments.

In addition to the material, the size and shape of the air loop gasket also play a crucial role in noise reduction. The gasket must be properly sized and shaped to create a tight seal between the surfaces it is sealing. A gasket that is too small or too large may not effectively reduce noise levels as it will not provide a proper seal. It is essential to measure the dimensions of the surfaces carefully before selecting an air loop gasket to ensure a proper fit.

Another factor to consider when choosing air loop gaskets for noise reduction is the operating conditions of the environment. Different environments have varying levels of noise pollution, and the gasket selected must be able to withstand these conditions. For example, gaskets used in outdoor environments must be resistant to weather elements such as rain, sunlight, and temperature fluctuations. Similarly, gaskets used in high-temperature environments must be able to withstand heat and pressure without losing their effectiveness in reducing noise levels.

Furthermore, the installation method of the air loop gasket is also an essential consideration when selecting gaskets for noise reduction. The gasket must be installed correctly to ensure a tight seal between the surfaces and prevent any gaps that may allow noise to escape. Proper installation techniques such as using adhesive or fasteners can help enhance the noise reduction capabilities of the gasket.

In conclusion, air loop gaskets play a crucial role in noise reduction in various industrial settings. When choosing gaskets for noise reduction, factors such as material, size, shape, operating conditions, and installation method must be carefully considered to ensure optimal noise reduction capabilities. By taking these factors into account, industries can effectively reduce noise pollution and create a quieter and more comfortable working environment for their employees.

- Maintaining and Upgrading Air Loop Gaskets for Long-term Noise Reduction Success

Air Loop Gaskets play a crucial role in noise reduction in various industries, particularly in HVAC systems where noise can be a major concern. These gaskets are designed to create a seal between the air duct and the HVAC system, preventing air leaks and reducing noise levels. However, simply installing air loop gaskets is not enough to ensure long-term noise reduction success. Maintenance and upgrades are essential to keep the gaskets in optimum condition and maximize their effectiveness.

Maintaining air loop gaskets involves regular inspections to check for any signs of wear and tear. It is important to look for cracks, tears, or gaps in the gaskets that could compromise their sealing capabilities. In addition, cleaning the gaskets regularly to remove dirt and debris is also recommended. This will help prevent any build-up that could affect the gaskets' performance.

Upgrading air loop gaskets may be necessary if they are not providing the desired level of noise reduction. In some cases, older gaskets may need to be replaced with newer, more advanced versions that offer better soundproofing properties. Upgrading to high-quality gaskets made from durable materials can significantly improve noise reduction and ensure long-term success.

One of the key benefits of maintaining and upgrading air loop gaskets is improved energy efficiency. When gaskets are properly sealed and in good condition, they help prevent air leaks and maintain the desired temperature in the HVAC system. This can lead to lower energy consumption and reduced utility costs. In addition, well-maintained gaskets can also improve indoor air quality by preventing the entry of dust, allergens, and other pollutants.

Another important aspect of air loop gasket maintenance and upgrades is safety. Faulty gaskets can lead to air leaks, which can result in a decrease in system efficiency and potentially pose a safety hazard. Regular inspections and upgrades help ensure that the gaskets are functioning properly and help prevent any accidents or damage to the HVAC system.

In conclusion, air loop gaskets are essential components of noise reduction in HVAC systems. Maintaining and upgrading these gaskets is crucial to ensuring long-term success in noise reduction, energy efficiency, and safety. By keeping gaskets in good condition and investing in upgrades when necessary, industries can enjoy a quieter and more efficient working environment.

Conclusion

In conclusion, understanding the importance of air loop gaskets in noise reduction is essential for creating a peaceful and comfortable environment. By effectively sealing off air leaks and preventing sound transmission, these gaskets play a crucial role in minimizing noise pollution and enhancing the overall quality of life. Whether in residential or commercial settings, investing in high-quality air loop gaskets can lead to significant improvements in acoustic performance. So, next time you’re looking to reduce noise levels and create a more peaceful atmosphere, don’t forget to consider the importance of air loop gaskets in your soundproofing strategy.

ABOUT US