Conductive Fabric

What is Conductive Fabric?

Conductive fabric—also referred to as metallized fabric or EMI shielding fabric—is a textile substrate (such as polyester, nylon, fiberglass or cotton) coated or woven with conductive metals like copper, nickel, gold, or carbon. These materials combine excellent electrical conductivity, flexibility and corrosion resistance, making them well suited for EMI/ESD shielding, grounding and signal isolation across electronics, telecommunications and medical industries.

Copper-Nickel Conductive Fabric

A textile overlaid with nickel/copper plating that provides strong conductivity and effective EMI shielding at a cost‐effective level. It is ideal for general electronics and enclosure applications.

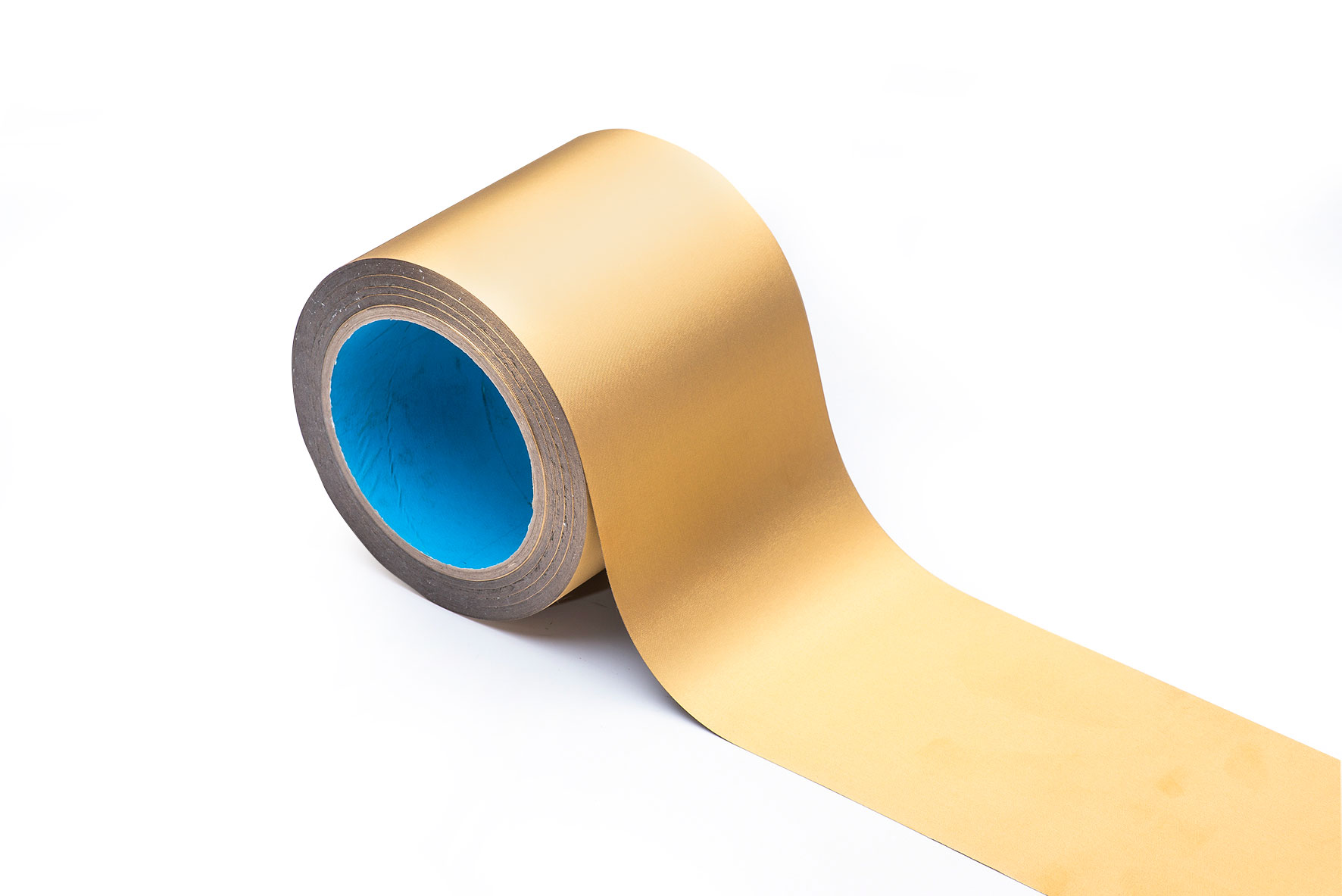

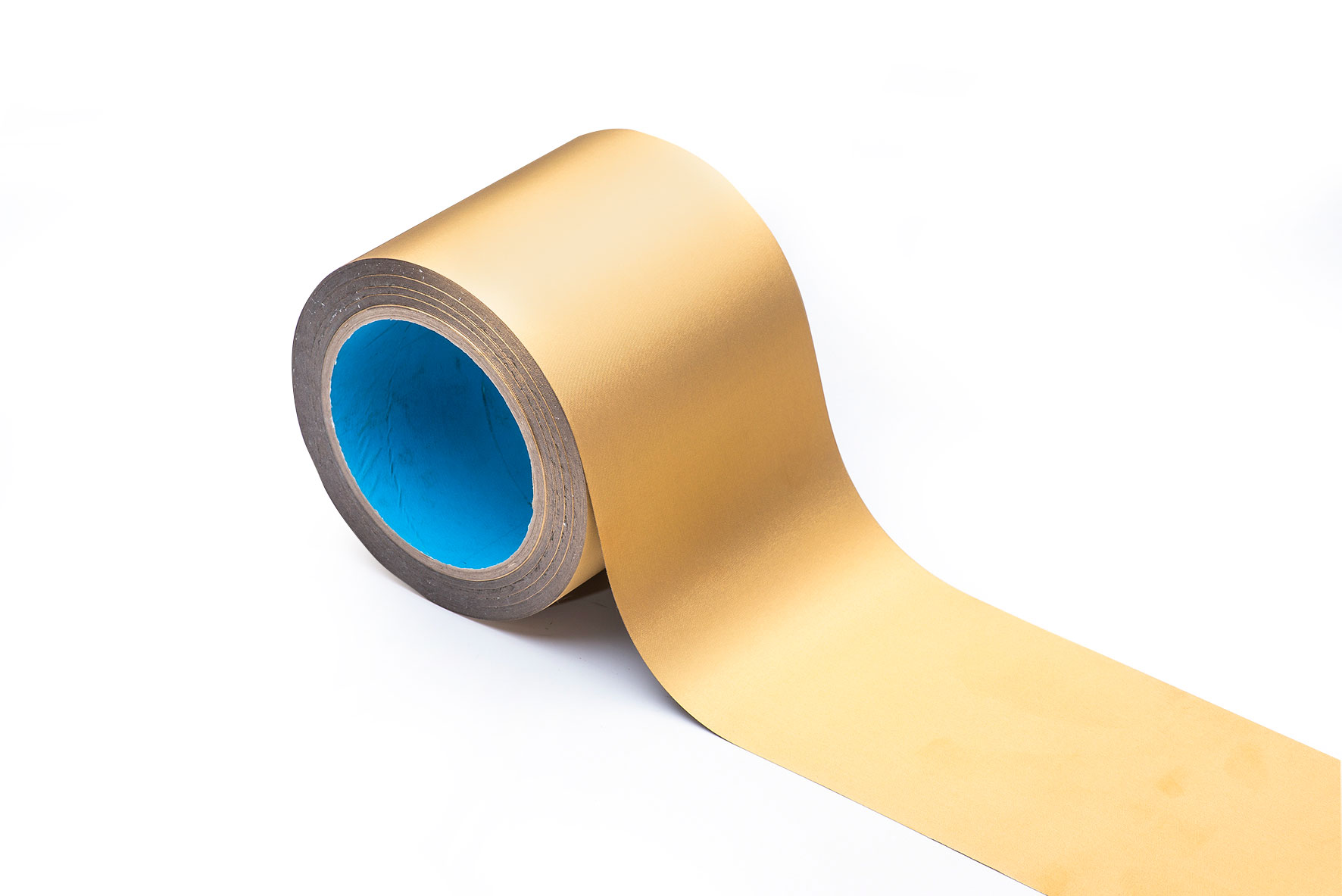

Gold-Plated Conductive Fabric

A fabric backed by polyester or nylon and plated with gold (or copper/nickel/gold combination), offering high conductivity along with oxidation and corrosion resistance. Perfect for premium electronics shielding where longevity and performance are required.

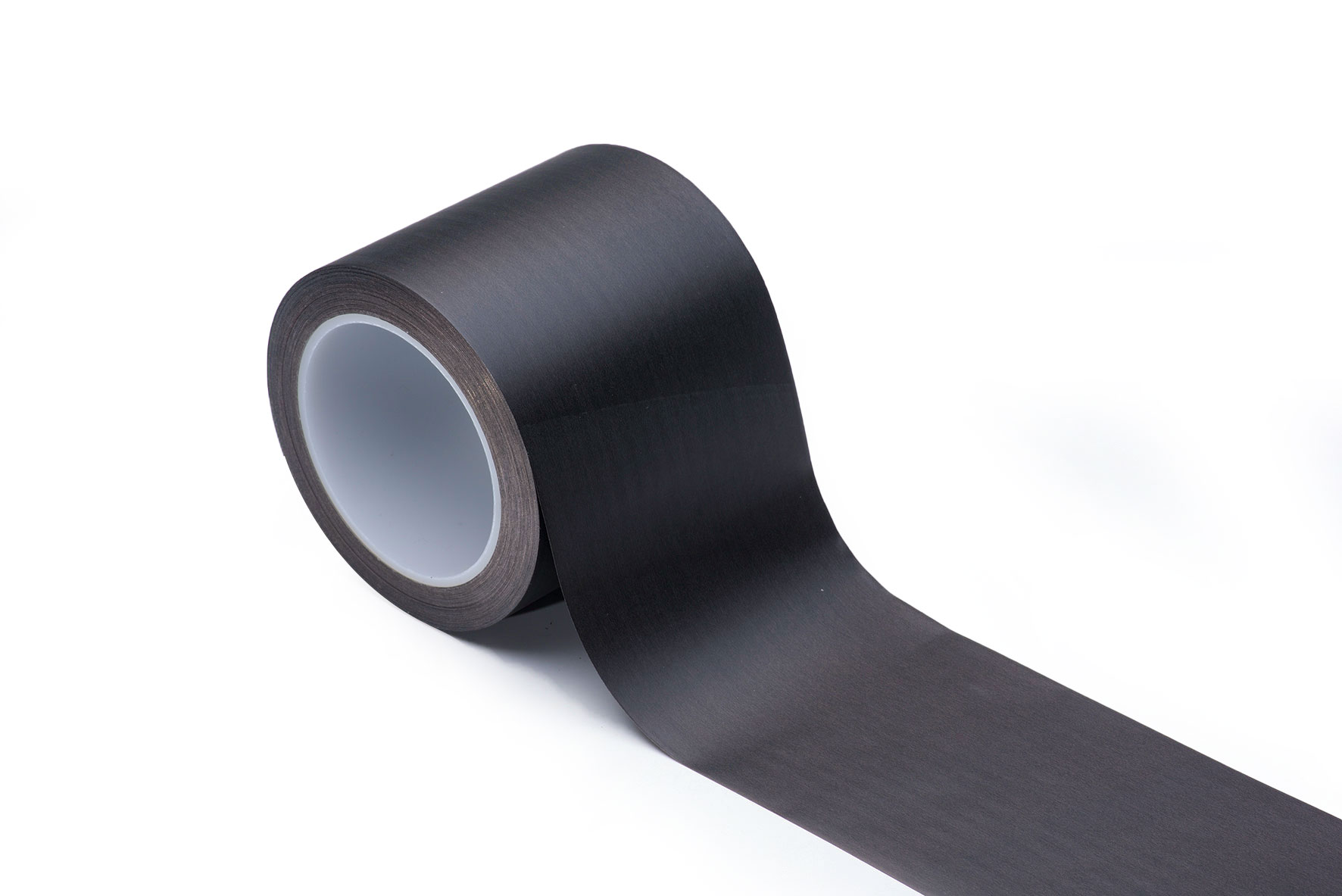

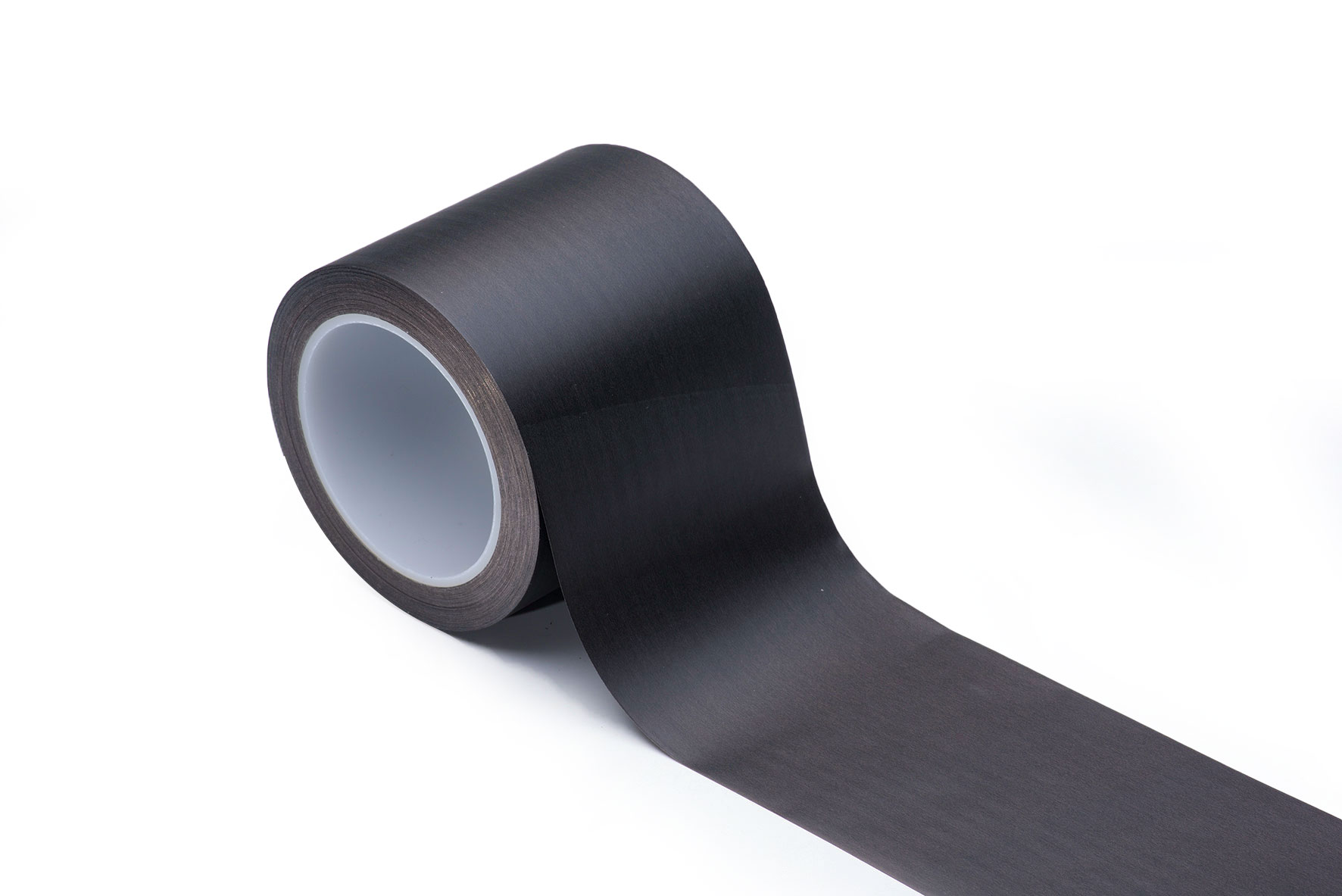

Black Conductive Fabric

A lightweight textile with a carbon or black-nickel conductive finish, optimized for electrostatic discharge and shielding in slim or concealed spaces. Its ultra-thin form factor makes it ideal for embedded and precision applications.

How does it work?

Depending on the surface resistance and structure, they can perform signal transfer, static discharge, or thermal dissipation functions.

KONLIDA’s conductive fabrics maintain stable conductivity even under repeated bending or compression, making them suitable for dynamic applications such as connector interfaces or moving enclosure seams.

What are Common Uses?

Conductive fabrics are widely used in EMI shielding, ESD protection, and grounding applications across various electronic devices and enclosures.

They serve as a key surface material in fabric-over-foam (FoF) gaskets, I/O shielding gaskets, and electronic housings to prevent signal leakage and static discharge.

Beyond traditional shielding, conductive fabrics are also applied in medical sensors, wearable electronics, automotive systems, and smart terminals, where lightweight and flexible conductivity is essential.

Features

Lightweight, flexible, and reliable—ideal for modern EMI/ESD solutions.

High Conductivity

Excellent Flexibility

Lightweight Design

Easy Processing

Flame Resistant

Eco-Friendly

Applications

Specifications/Data

| Copper-Nickel Conductive Fabric |

|

|

|

| Materials | Nickel+Copper+Polyester Fiber+PU Coating |

| Color | Gray |

| Thickness | 0.05mm (Customizable) |

| Width | 1080mm (Customizable) |

| Vertical Resistance | ≤0.05Ω/Sq |

| Surface Resistance | ≤0.05Ω/Sq |

| Shielding Efficiency | >60db (30MHz-3GHz) |

| Metal Layer Adhesion | Level 3 |

|

Gold-Plated Conductive Fabric |

|

|

|

| Materials |

Gold+Nickel+Copper+Polyester |

| Color | Golden |

| Gram Weight | 65g/m2 |

| Thickness | 0.05mm (Customizable) |

| Width | 520mm (Customizable) |

| Length | ≤400m (Customizable) |

| Fabric Density | 380T (Customizable) |

| Surface Resistance | ≤0.02Ω/Sq |

| Shielding Efficiency | >70db (10MHz-3GHz) |

| Abrasion Resistance Test | 10000 times |

| Black Conductive Fabric |

|

|

|

| Materials | Carbon+Nickel+Copper+Polyester |

| Color | Black |

| Thickness | 0.03mm (Customizable) |

| Width | 1060mm (Customizable) |

| Vertical Resistance | <0.1Ω/Sq |

| Surface Resistance | ≤0.3Ω/Sq |

| Shielding Efficiency | >60db (30MHz-3GHz) |

| Metal Layer Adhesion | Level 3 |

Get in touch with us

Conductive Fabric

What is Conductive Fabric?

Conductive fabric—also referred to as metallized fabric or EMI shielding fabric—is a textile substrate (such as polyester, nylon, fiberglass or cotton) coated or woven with conductive metals like copper, nickel, gold, or carbon. These materials combine excellent electrical conductivity, flexibility and corrosion resistance, making them well suited for EMI/ESD shielding, grounding and signal isolation across electronics, telecommunications and medical industries.

Copper-Nickel Conductive Fabric

A textile overlaid with nickel/copper plating that provides strong conductivity and effective EMI shielding at a cost‐effective level. It is ideal for general electronics and enclosure applications.

Gold-Plated Conductive Fabric

A fabric backed by polyester or nylon and plated with gold (or copper/nickel/gold combination), offering high conductivity along with oxidation and corrosion resistance. Perfect for premium electronics shielding where longevity and performance are required.

Black Conductive Fabric

A lightweight textile with a carbon or black-nickel conductive finish, optimized for electrostatic discharge and shielding in slim or concealed spaces. Its ultra-thin form factor makes it ideal for embedded and precision applications.

How does it work?

Depending on the surface resistance and structure, they can perform signal transfer, static discharge, or thermal dissipation functions.

KONLIDA’s conductive fabrics maintain stable conductivity even under repeated bending or compression, making them suitable for dynamic applications such as connector interfaces or moving enclosure seams.

What are Common Uses?

Conductive fabrics are widely used in EMI shielding, ESD protection, and grounding applications across various electronic devices and enclosures.

They serve as a key surface material in fabric-over-foam (FoF) gaskets, I/O shielding gaskets, and electronic housings to prevent signal leakage and static discharge.

Beyond traditional shielding, conductive fabrics are also applied in medical sensors, wearable electronics, automotive systems, and smart terminals, where lightweight and flexible conductivity is essential.

Features

Lightweight, flexible, and reliable—ideal for modern EMI/ESD solutions.

High Conductivity

Excellent Flexibility

Lightweight Design

Easy Processing

Flame Resistant

Eco-Friendly

Applications

Specifications/Data

| Copper-Nickel Conductive Fabric |

|

|

|

| Materials | Nickel+Copper+Polyester Fiber+PU Coating |

| Color | Gray |

| Thickness | 0.05mm (Customizable) |

| Width | 1080mm (Customizable) |

| Vertical Resistance | ≤0.05Ω/Sq |

| Surface Resistance | ≤0.05Ω/Sq |

| Shielding Efficiency | >60db (30MHz-3GHz) |

| Metal Layer Adhesion | Level 3 |

|

Gold-Plated Conductive Fabric |

|

|

|

| Materials |

Gold+Nickel+Copper+Polyester |

| Color | Golden |

| Gram Weight | 65g/m2 |

| Thickness | 0.05mm (Customizable) |

| Width | 520mm (Customizable) |

| Length | ≤400m (Customizable) |

| Fabric Density | 380T (Customizable) |

| Surface Resistance | ≤0.02Ω/Sq |

| Shielding Efficiency | >70db (10MHz-3GHz) |

| Abrasion Resistance Test | 10000 times |

| Black Conductive Fabric |

|

|

|

| Materials | Carbon+Nickel+Copper+Polyester |

| Color | Black |

| Thickness | 0.03mm (Customizable) |

| Width | 1060mm (Customizable) |

| Vertical Resistance | <0.1Ω/Sq |

| Surface Resistance | ≤0.3Ω/Sq |

| Shielding Efficiency | >60db (30MHz-3GHz) |

| Metal Layer Adhesion | Level 3 |

Get in touch with us

ABOUT US